The Truth About Set Screws

Round Tip vs. Cupped Tip

There are a lot of rumors and myths regarding roof clamp set screws and how they attach to standing seam metal roofs. The competition has systematically made claims that cupped tip set screws scratch and gall the seams, thereby voiding the roof warranties and causing premature corrosion. This has been repeated in their marketing materials, website, AIA continuing education courses and in live seminars. Simultaneously, they also boast that they have a special “patented” round tip set screw that allegedly doesn’t scratch the panel or harm it in any way, thereby “protecting the fragile paint finish” and warranty.

To answer this marketing hype, we have decided that it was time to actually test both types of set screws by installing them on the same test panels and evaluating the validity of their claims. We are going to answer the following questions with our testing:

- Do cupped tip set screws actually expose bare metal to the elements thereby causing premature corrosion?

- Do round tip set screws scratch the paint or expose bare metal to the elements?

- How does the proper installation of either clamp effect the integrity of the seam?

Both round tip and cupped tip set screws have been used since the early 1990’s in metal roof clamps from various manufacturers. Clamps with cupped tip set screws and round tip set screws actually attach to the seams in very different ways. The cupped tip screws create a positive anchor point when properly torqued to 90in./lbs. while round tip set screws rely on high torque and panel compression to stay in place. In order for the clamps that utilize round point set screws to stay in place under load, they must be torqued to 130-150in./lbs. or even as high as 160-180in./lbs. for 22ga. panels. The video demonstration will show the results of using high compression round point set screws vs. cupped point set screws.

Interesting Fact: Did you know that it is public record that Action Manufacturing, LLC a.k.a SnoBar was the FIRST company to apply for a patent for a U-Shape non penetrating clamp for use with a snow retention system?

Clamp Test using Round Tip Set Screws

This demonstration shows the S-5U and the S-5S clamp using Round Tip set screws. We are using the exact same 24ga. Snap Lock test panels that were used to test the SnoBar clamp with cupped tip set screws. This company boldly claims that all other set screws harm the panels except for their “specially designed patented round tip set screws”. Although we have requested the patent information for their “special” screws, it has not been provided nor has it been explained what the difference is when compared to a common oval point set screw.

Installation was done according to the manufacturer's installation instructions and the set screws were properly torqued between 130-150in./lbs. according to manufacturer’s recommendation for 24ga. panels. The video will document the installation, the amount of seam distortion and "panel dimpling" on both sides of the panel. The clamps are installed and then carefully removed. On a side note, we found the clamp with the round tip set screws can take much longer to install than the SnoBar clamps which debunks the competition's claim that installers often charge less to install the clamp with round tip set screws."Only S-5!® utilizes special polished, round-tipped screws. Although more costly, the makers of S-5!® use this patented method to preserve delicate panel finishes — and their warranties." -S-5 Web Site

"Our patented setscrews are designed to dimple the seam material without puncturing, scratching or harming it." -S-5 Web Site

"be sure that fasteners do not overly distort the seam and that they have a round polished point so that the seam material is not gouged, destroying the finish or causing corrosion." S-5 AIA Course Pg 78/114 Rob Haddock "S-5 Web Site"

Click images to view full size.

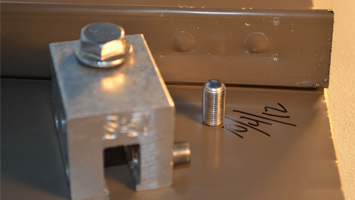

SnoBar Clamp Test using Cupped Tip Set Screws

In this demonstration we will use the stainless steel SnoBar clamp utilizing "Cupped Tipped" set screws. This is the clamp that has been sold along with the SnoBar and ColorBar snow retention systems since the early 1990's. Our test panels are the same typical 24ga. Snap Lock style panels that we tested the S-5U and the S-5S clamps on. The SnoBar manufacturer recommends a torque setting of 90in./lbs. and the two cupped tip set screws are opposing each other. This allows for extremely fast installation since one set screw can be preset while the other screw is torqued to 90in./lbs. Once the clamp is installed, you can clearly see that there is very little seam distortion and no extraneous scratches or breeches in the painted surface around the screws.

Although the clamps and screws are designed to be permanently attached, this experiment requires us to remove the clamp to show the consumer what the attachment point looks like. The cupped tip set screws fit perfectly in the attachment point without penetrating the seam or exposing bare metal to the elements. While it is true that the cupped tip set screws will penetrate the painted finish to produce a positive lock to the panel, this area is permanently sealed between the tip of the set screw and the seam, therefore eliminating exposure to the elements. These images clearly show an undamaged seam profile and side views showing no exposed bare metal when the SnoBar clamp is properly torqued to 90in./lbs..

Click images to view full size.

Conclusion

This entire demonstration clearly refutes the following claims made by S-5 in marketing materials, website, AIA Continuing Education class, and in live seminars.

"a "cup" point gouges through protective coatings violating warranties and causing corrosion sites at the point of attachment." -S-5 Web Site

"Parts that attach with clamping mechanisms should be carefully scrutinized. A cup point set screw, for instance gouges the metal to dig in. This can violate finish warranties and cause premature corrosion sites." -S-5 Web Site

These unjustified claims imply that roof panels are so delicate that any scratches will cause a warranty to be voided and will also invite premature corrosion. The fact is, every metal panel has exposed bare metal on all the edges, at the cut ends and sometimes even around screw holes. If these common installation techniques are a catalyst for corrosion, then would it be accurate to assume that just about every metal roof in the field would be corroding at each cut end, on all cut edges and around the screw holes? This is simply not the case and it is absurd to advocate this farce. To the best of our knowledge, there has never been a warranty voided because of cupped tip set screws that were properly used on a metal roof nor have we ever seen premature corrosion in the attachment areas of properly installed clamps with cupped tip set screws.

Based on our testing, it seems that there are some serious inconsistencies between the competition's claims and our actual test results. When the round tip set screws are properly torqued between 130-150in./lbs., the contact point of a round tip set screw CAN breech the delicate paint finish and the body of the clamp can also scratch the paint down to bare metal.

We also documented the fact that when the round tip set screws are properly torqued, they do dimple the set screw side of the seam. However, on our test panels, they also stretch the metal on the opposite side. The result can be breeched paint rings around the stretched metal areas as demonstrated in our video.

Since the clamps are designed for permanent installation, some of the paint damage will be covered by the set screws and the body of the clamps, however some the breeched paint areas on the opposite side of the panel(shown in the above picture) can potentially be exposed to the elements.

In summary, we tested the clamps in response to misleading marketing claims made by the competition. Our tests demonstrated that properly installed SnoBar clamps using cupped tip set screws are actually LESS likely to expose bare metal to premature corrosion than properly installed clamps using round tip set screws. Our tests have also proven that higher torque set screws (round tip) can cause considerably more seam distortion than the 90in./lbs. of torque required on cupped tip set screws.

In closing, it’s fair to say that any set screw can breech the paint when properly installed on metal roof panels. There are no special set screws that magically protect the paint finish, but the truth is that some set screws do far less damage than others. Unfortunately, misleading claims about cupped tip set screws have gone unchallenged for years and serious damage has been done to their reputation, but in the end, the truth always prevails! After reviewing the video we would like you to decide if the claims made against cupped tipped set screws are true or false, so please watch the demonstration video and share it with the design professionals in your industry.

Click images to view full size.